Solution

Liquid Detection and Analysis

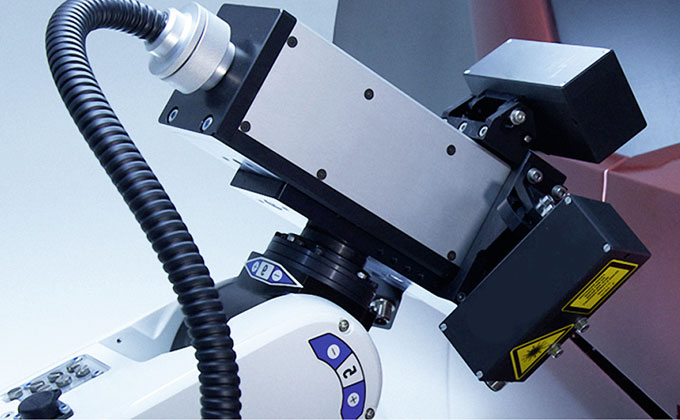

Terahertz technology holds significant market potential in liquid analysis, offering a rapid, non-destructive, and non-invasive method for characterization. Using advanced techniques such as attenuated total reflection (ATR), terahertz waves can be effectively coupled into liquid samples, enabling precise measurement of key parameters. For instance, terahertz ATR is highly effective for monitoring cleaning solutions, providing real-time data on chemical composition, concentration changes, and contamination levels without direct sample extraction.

This capability is crucial for quality control in manufacturing processes—ensuring consistency in critical cleaning baths for semiconductors, automotive components, and precision machinery. Beyond industrial cleaning, terahertz liquid analysis extends to sectors like pharmaceuticals (solvent verification), petrochemicals (fuel quality), and food & beverage (concentration monitoring). By delivering instant, reliable insights, terahertz technology not only enhances process efficiency and safety but also paves the way for smarter, more automated industrial fluid management systems.